About

With Anza Industrial & Coatings you ensure the right coating thickness in all layers of the coatings sandwich, avoiding costly extra coats or complete do-overs. Spend a little more on quality application tools for the predictability and the quality of the protection achieved with your coating solution.

IT DOES NOT HELP TO HAVE THE BEST PAINT IN THE WORLD IF THE PREPARATION OR APPLICATION IS NOT RIGHT.

Anza Industrial and Coatings have been developed with leading producers of industrial coatings and thoroughly tested to ensure that the products can deliver on our promise: “get it right the first time”.

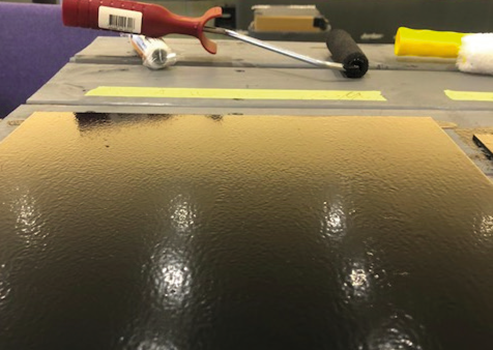

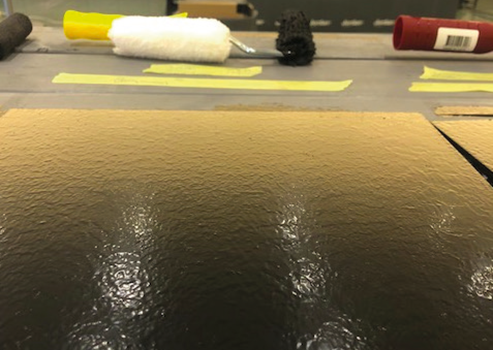

This picture shows a polysiloxane topcoat applied with a roller designed for high viscosity, demonstrating the importance of the right application tools to achieve coverage and correct film thickness.

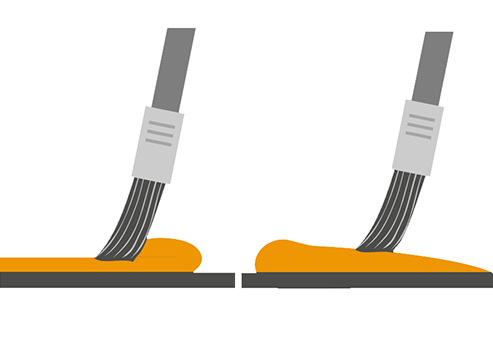

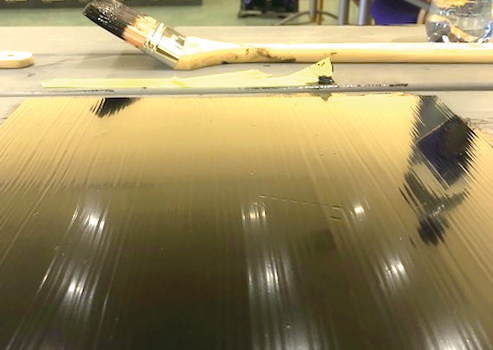

A quality brush delivers an even film thickness throughout the stroke (left), whereas a brush of lower quality deposits most of the paint in the beginning of the stroke (right).

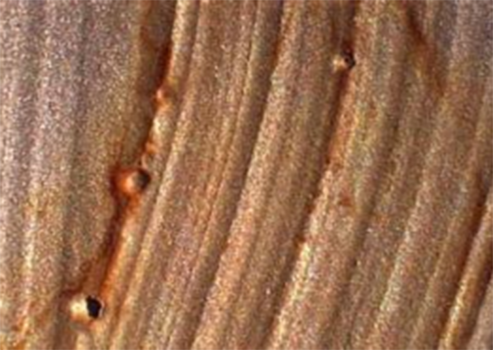

Fibre loss from a roller in coating film can create a pathway for moisture to reach the substrate.

Quality application tools ensure there is no fibre loss.

Rust spots and blisters follow brush marks due to low DFT.

Uniform coating film with blistering and rust spots due to low film thickness (DFT).

The pictures below show the large difference in results you can get using the same coating but applied with different types of rollers. On the panels with low DFT you can also see poor opacity.

35-65 microns DFT.

35-70 microns DFT.

70-85 microns DFT.

80-160 microns DFT.

LAB TESTING:

Roller development.

Brush development.

Anza Industrial & Coatings 175–200 microns WFT.

Competitor 175–200 microns WFT.

Anza Industrial & Coatings 130–150 microns WFT.

Competitor 75–125 microns WFT, fibre loss.

LIVE TEST AT KLEVEN SHIPYARD, ULLSTEINVIK:

Application with Anza Industrial & Coatings paint roller.

Measuring film thickness.

Anza Industrial & Coatings 125–176 microns WFT (left). Competitor 25–175 microns WFT (right).

Anza Industrial & Coatings 100–125 microns WFT (left). Competitor 25–75 microns WFT, fibre loss (right).

Anza Industrial & Coatings is part of the Orkla House Care portfolio. Our history of developing and manufacturing painting tools can be traced back more than 250 years, always with a focus on the right quality painting tool for the job at hand. So why not take advantage of this experience and contact us for a chat with no obligations, to find the right solution for your application?